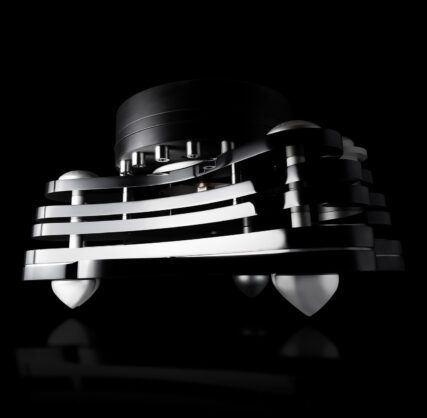

The most ambitious turntable ever made by Gold Note

In order to achieve absolute prestige sound quality, Bellagio Reference uses five different curved boards that guarantee maximum rigidity and non-deformability, allowing for the best possible control of resonance. The boards are connected to each other by aluminum plates that increase their damping capacity. Bellagio Reference can also boast one of the best platter spindles ever made for a turntable. To ensure extraordinary efficiency, the platter spindle is made of the hardest carbon steel alloy, C40, tempered, ground and polished to ensure virtually perfect rotation. The socket is made of ground and lapped bronze to ensure a mating tolerance of 1/100mm with the pin. Bellagio Reference is beauty, form and technique at the service of sound.

Bellagio Reference is equipped with a 12V synchronous motor driven by a proprietary power supply managed by a micro-controller developed with the help of an audio converter and a Quadral-Core micro-processor that completely reconstructs and filters the electric wave, guaranteeing high rotation precision, high torque and at the same time a complete elimination of motor vibrations. The motor power electronically controls the 33/45rpm speed and is finely adjustable, the settings are permanently stored inside the power supply micro-controller even in the absence of external power.

MAIN FEATURES

POWER

DIMENSIONS AND WEIGHT

FINISHES

UPPER PLINTH

Black polished acrylic or Gold leaf

MAIN PLINTH

Black polished acrylic and titanium

Gold leaf and titanium

METAL PARTS

Black

PLATTER

Black